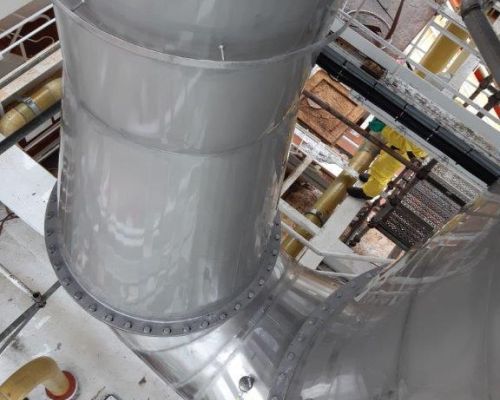

ISTECH Metal Finish BV - Marine Scrubber Repair Services

STAINLESS STEEL EXHAUST GAS SCRUBBER MAINTENANCE AND REPAIR

It is imperative that the structural integrity of the scrubber and associated pipework is constantly checked for signs of leakage or corrosion. In view of the acidic nature of the scrubber washwater, correct material selection for the scrubber body, pipework, components and accessories, together with good installation, but also very important, maintenance and repair workmanship are critical to avoid subsequent safety issues.

ISTECH Marine Scrubber Service and Repair Team specializes in Stainless Steel Surface Treatment and Stainless Steel Surface Repair by Welding, Grinding and Polishing. Our Team members are Stainless Steel Specialists, Corrosion Experts, Qualified Welders and highly skilled Fitters.

ISTECH Metal Finish BV - Stainless Steel Treatment and Repair Services provides the following high quality technical services on site / on board in the best interest of your MARINE Scrubber regarding:

- Emergency Service (24/7) for Welding Repairs and Troubleshooting

- Stainless Steel Condition Inspection

- Stainless Steel Corrosion Inspection

- Stainless Steel Surface Corrosion Damage Reports

- Stainless Steel Weld Inspection (NDT / Dye-Check)

- Stainless Steel Passivity Testing

- Stainless Steel Surface Roughness Testing

- Stainless Steel Surface Repair by Welding, Grinding and Polishing

- Stainless Steel Surface Treatment by Pickling and Passivation

- Removal of Corrosion on Stainless Steel Materials

- Interior Piping Inspection (endoscope camera)

- Stainless Steel Pitting Corrosion Scanning

- High Pressure Cleaning by (Ultra) High Pressure Water Jetting

Qualified welders for high quality welding repairs on marine scrubbers

Our welders are qualified and trained to know skill in performing the Welding Process to comply with the relevant Welding Procedures. Our qualified welders have many years of working experience in the field of welding repairs on corrosion resistant Stainless Steel Alloys and Metal Materials such as:

- SUPER DUPLEX

- ALLOY 39

- ALLOY 59

- 254 SMO

- TITANIUM

- (STAINLESS STEEL 316/316L)

Extensive knowledge of exhaust gas scrubbers and repair

ISTECH Marine Scrubber Service and Repair Team has qualified welders and highly skilled fitters specializes in repair works on Marine Scrubbers of various brands, such as:

- Wärtsilä

- Valmet

- Value Maritime

- Clean marine

- Ecospray

- Pacific Green

- Yara Scrubbers

Extensive knowledge of Marine Scrubbers regarding Surface Treatment, welding Repairs and condition inspectIons

ISTECH Stainless Steel Marine Scrubber Surface Treatment and Repair Service Team has extensive knowledge of:

- Stainless Steels Surface Corrosion Treatment

- Stainless Steel Chemical Surface Treatment

- Stainless Steel Mechanical Surface Treatment

- Stainless Steel Surface Welding Repair

- Stainless Steel Condition Inspection and Report

- Stainless Steel Corrosion Damage Inspection and Report

MARINE SCRUBBERS TO COMPLY WITH IMO 2020

An exhaust gas cleaning system, also known as scrubber or gas scrubber, is a device installed on board of marine vessels that, quite literally, “scrubs” harmful sulfur oxides from exhaust gases. The technology is commonly installed on ships seeking compliance options in the face of tighter emissions regulations conform the new International Marine Organisation emission regulations. The new emission regulations, known as IMO 2020, mandates a maximum sulphur content of 0.5% in marine fuels globally.

Marine Scrubbers have been among the top choices for owners to comply with IMO 2020 Sulphur Cap, as an alternative to low-sulphur fuels, primarily due to the cost savings they offered to owners of large ships as compared to expensive new fuels.

Welding Procedure Standard NEN-EN-ISO 15614-1

ISTECH Metal Finish BV carries out welding repairs according to Welding Procedure Standard NEN-EN-ISO 15614-1, level 2. We carry out inspections during welding and upon completion, performed by qualified engineers.

Full service

Our goal is to get the job done with minimum of Downtime and our Service and Repair Team is 24/7 standby and always ready to go anywhere in the world. We keep in direct contact with Fleet Managers, Technical Managers, Chief Engineers, Ship Owners, Ship Agents, Port Authorities and can take care of Hot Work permits. We can also arrange Launch services to Anchorspots.

- Inspection & Troublshooting

- Welding Repairs

- Grinding and Polishing

- Pickling and Passivation

- Chemical and High Pressure Cleaning

Marine Scrubber is a system that is designed to by the use of water wash the exhaust gases from main, auxiliary and boilers to remove sulfur dioxide (SO2) which is a toxic gas, that is directly harmful to human health. There different designs in the market today however they could be divided into two categories, open and closed types. Power consumption of operating a scrubber system is typically between 1-2% of main engine power.

Marine Gas Scrubber Cleaning Operations & Surface Treatment Services - Pickling and Passivation

After Pickling and Passivation

-

Stainless Steel Scrubber Interior High Pressure Cleaning

-

Stainless Steel Marine Scrubber Interior Pickling and Passivation

-

Stainless Steel Scrubber Passivity Readings after Pickling and Passivation

Stainless Steel Scrubber Corrosion Problems

- Ferrous contamination during installation on board

- Poor surface treatment during fabrication

- Both above in combination with seawater

Ferrous Contamination:

The residue is free (unAlloyed) iron on the surface. Free iron should not be confused with Alloyed iron which is a major component of stainless steel, or with ferrite which is a specific type of crystalline structure and a normal component of stainless steel, especially cast stainless steel. If non-sufficient surface treatment of the stainless steel on completion of fabrication and / or installation on board will definitely resulted in an active surface condition instead of the required passive surface condition. This will give free iron the opportunity to embed itself so that the passive oxide film shall been penetrated through this ferrous contamination. Iron residue may also be transferred to Stainless steel surfaces from materials which were previously used on steel or iron parts. Of course, iron or steel shot or grit used to remove scale or other materials from the Stainless steel items would leave iron residue on the surface. One of the most difficult sources of iron residue to avoid is the atmosphere itself. Industrial areas have a surprising amount of iron in the air. This iron “falls out” onto exposed items, including previously cleaned Stainless steel parts. Also, water which is used to “clean” the surfaces may itself contain iron which will be deposited onto the surfaces thought to be clean. Note that water may also contain other chemicals which may leave rust-colored deposits which may be mistaken for indications of the presence of free iron. Appearance – Free, unAlloyed iron on the surface of any item will oxidize (rust) given the appropriate conditions (warmth, moisture, and oxygen). The reddish brown deposits are easily recognized Contamination on Stainless steel surfaces with free iron is common. It can be avoided only with very careful and correct surface treatment including professional pickling and passivation and related technical cleaning processes.

ISTECH Metal Finish - Stainless Steel Treatment and Repair Services

ISTECH Metal Finish BV specializes in Stainless Steel Scrubber Surface Treatment and Welding Repair Services Worldwide for:

- Emergency Service (24/7) for Welding Repairs

- Troubleshooting for Stainless Steel Repair and Corrosion Treatment

- Modification works on Scrubber installations

- High Quality Welding

- Stainless Steel Chemical Surface Treatment

- Stainless Steel Mechanical Surface Treatment

- Stainless Steel Welding Repair

- Stainless Steel Condition Inspections

STAINLESS STEEL SURFACE BUFFING - GRINDING - POLISHING - WELDING

CLEANING OPERATIONS - PICKLING AND PASSIVATION